Hidrive: The hiway

At Hidrive, sustained success is founded on the principles established in our three pillars: People, Customers, and Quality. This proven but different approach is what we call The Hiway.

Our Journey

Our team

Leadership Team

Stan Eagle

CEO

Toby Dunlop

Chief Revenue Officer

Jeremy Carter

Head of Account Management

Melissa Humphries

Chief People Officer

Cameron Atkinson

Head of Engineering

Roger Eagle

Continuous Improvement Project Manager

Anthony Barbara

National Product Manager

Teri Cooper

Communications Manager

Ryan Pridham

Quality Manager

Mark McCarthy

National Service Manager

Nigel Rohrich

Procurement Officer

David Coleman

Supply Chain Planning Manager

Matt Robertson

Manufacturing Manager - Goulburn

Dylan Teeken

Production Manager - Installation

Alex Williams

National Sales Manager

Luke Charnock

National Optimisation Manager

Jane Naumoski

National HSEQ Manager

David Joyce

Chief Financial Officer

Reto Fuhrer

Chief of Operations

Danny Davies

Technical Procurement Manager

Mobile Workspace Specialists

Tim Grace

Trailer Specialist

Shaun Micallef

MOBILE WORKSPACE SPECIALIST - VIC & TAS

Wil Reyne

Mobile Workspace Specialist - QLD

John Lyon

Mobile Workspace Specialist - Qld

Lachlan Dunlop

National Account Manager

Brian Sharpe

Mobile Workspace Specialist - WA

Jedd Talbot

Mobile Workspace Specialist - SA & NT

Ryan Anson

Mobile Workspace Specialist – WA

Brittney Connell

Mobile Workspace Specialist - NSW & ACT

Emil Abellonar

Mobile Workspace Specialist - NSW

Customer Success Team

Lachlan Yule

Customer Success Manager

Jess Elliah

Order Manager

Jenny Langcay

Order Manager

Australian Manufacturing Excellence

Hidrive is Australia’s only manufacturer of service bodies for utes, trailers and trucks with a company-owned national installation network. We build fit-for-purpose aluminium canopies for trades and industry, and we are ISO 9001 (Quality), ISO 14001 (Environment) and ISO 45001 (Safety) compliant.

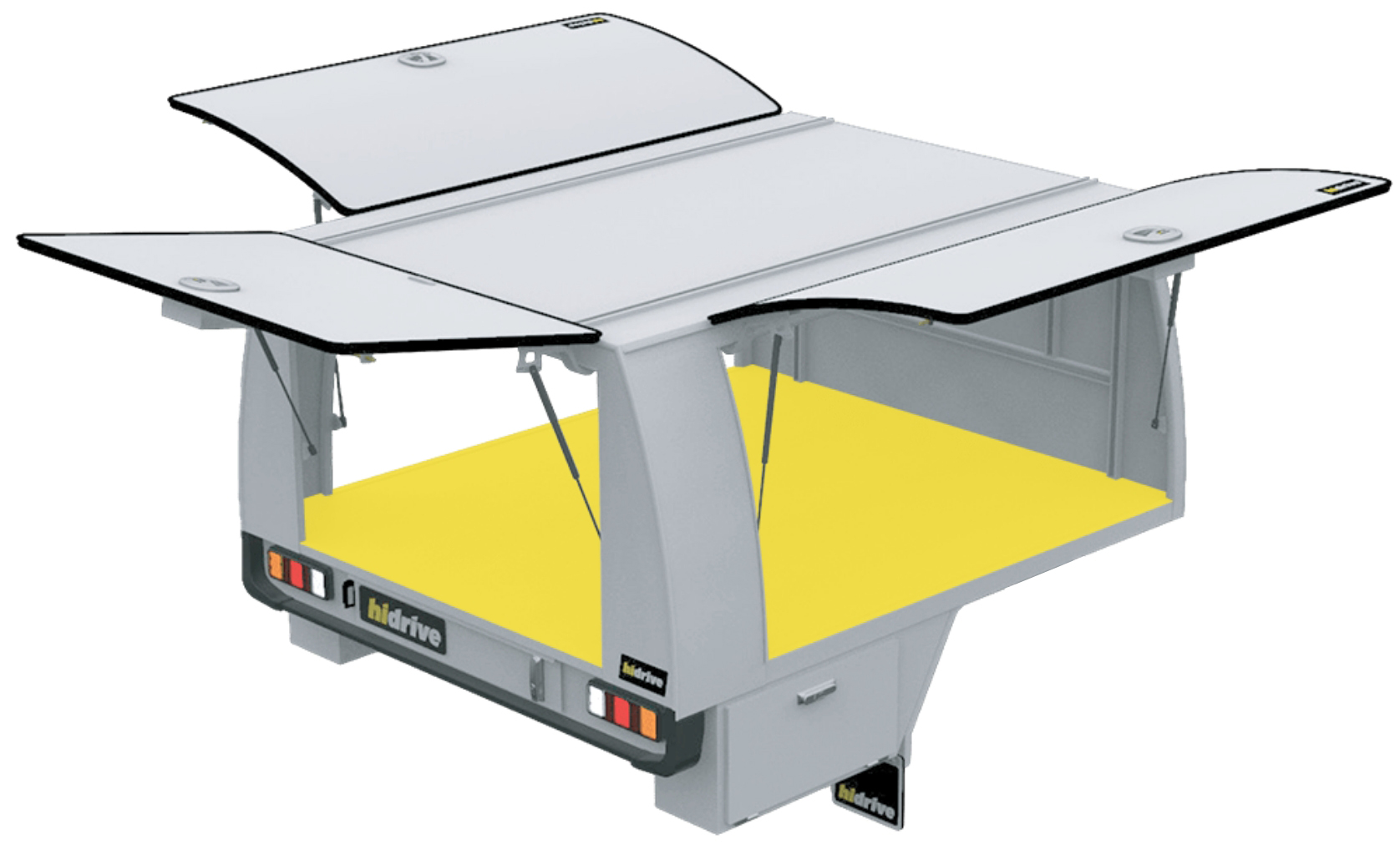

Hidrive is vertically integrated, offering over 190 modular and electrical accessories to turn your service body into a truly mobile workspace. These range from shelving, benches, roof storage and drawers, to towbars, inverters, lighting and much more.

Built like an aircraft fuselage, our light and strong aluminium canopies are engineered to maximise payload and stability, improve fuel efficiency, and be resistant to corrosion, UV damage and vibration.

Our service bodies have been bulletproof in the field since 1993. Through 32 years of continuous improvement, our products have evolved into the high-performance range you see today.

Why Choose Us?

Your 10 Point

Fit-for-purpose Checklist

|

Is it aluminium? for durability, the lowest weight and maximum payload? |

|

|

Can you work out of it? Gullwing doors that shelter from rain and sun? |

|

|

Will your gear move around? How will you fit, organise and tie-down tools and stock? |

|

|

Is it secure? e.g. central locking. |

|

|

Is your seal on the door? Seals around the entrance are easily damaged when loading or unloading, letting in dust/water thereafter. |

|

|

Is it durable? A Hidrive will not develop structural cracks or rust. |

|

|

Has it got integrated roof, ceiling, wall and underfloor fixing tracks? Consider how you’ll add or move accessories without drilling. |

|

|

Do your utes look, function and perform consistently? Ensure your team has a consistent fleet, nationally. |

|

|

Have you reviewed our 120 accessory groups? Ensure your mobile teams are productive. |

|

|

Do you have national safety compliance? Be ready for any mining, construction, airport or roadside job. |